Water-Activated Casting Technology: Resin Chemistry & Timing

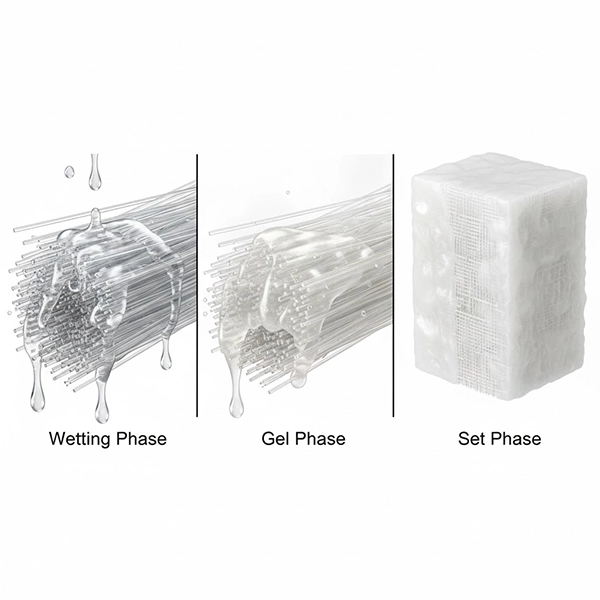

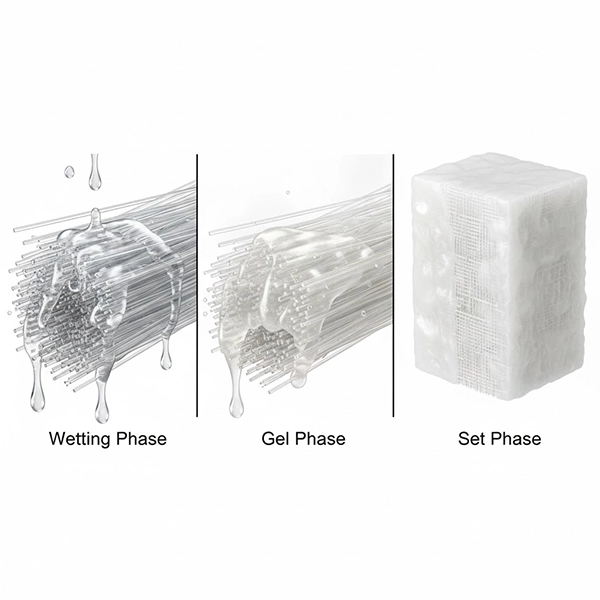

Fiberglass casting tapes consist of glass fibers coated with a water-activated resin. Controlled wetting initiates polymerization, passing through a defined working time, gel time, and final set time to form a light yet strong immobilization shell. Understanding resin chemistry and timing is crucial for precise molding, skin safety, and imaging compatibility.

Resin chemistry of water-activated tapes

Most systems use polyurethane-based or equivalent curable resins that react with water to crosslink. The reaction is:

- Water-initiated: controlled uptake at fiber surfaces triggers early gel formation.

- Exothermic: heat release scales with water temperature, reaction rate, and activated mass.

- Viscosity-tuned: engineered viscosity supports even overlap and under-cast ventilation.

Timing terms—wet to strong

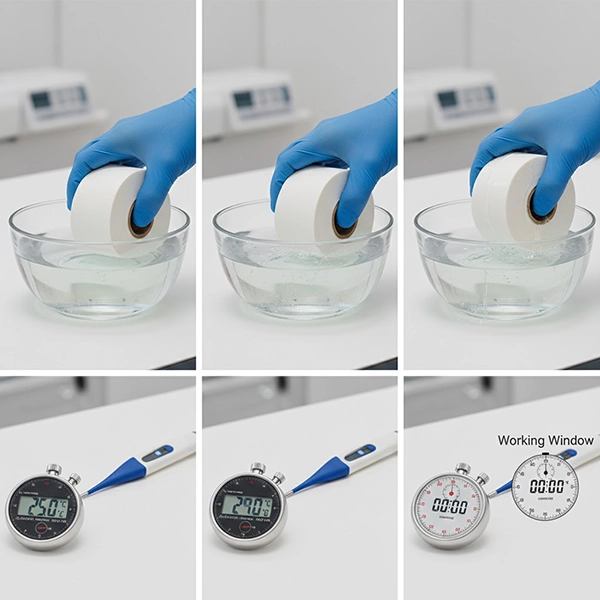

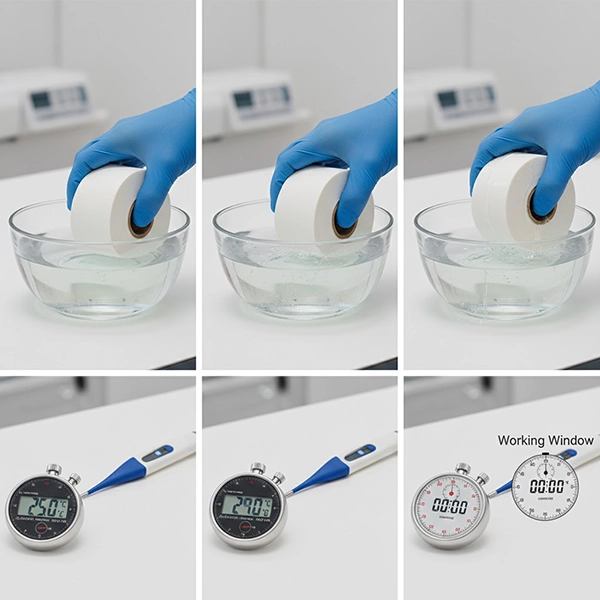

- Dunk time: 2–5 s immersion for complete wetting. Over-wetting ⇒ higher exotherm, shorter working time.

- Working time: soft to semi-rigid molding window; ~1.5–3.5 min depending on brand and temperature.

- Gel time: transition to tacky gel; complete overlaps before this point.

- Set time: initial structural strength in ~3–7 min, with continued strength gain thereafter.

How to control the working window

- Water temperature: keep it lukewarm (≈20–25 °C) for balance; hot water shortens the window and increases hot spots.

- Short, uniform wetting: 2–5 s is enough; gently squeeze to remove excess.

- Pre-staging: padding, tools, and limb position ready before activation.

- Continuous layup: 30–50% overlap with even tension; avoid long pauses.

Environmental factors

- Temperature: warmer room/water ⇒ faster set, shorter control; cooler ⇒ slower set, easier handling.

- Humidity: high RH can accelerate onset; intact packaging and proper storage are critical.

- Activated mass: more rolls/layers at once ⇒ more cumulative exotherm and shorter working time.

Thermal safety & skin protection

- Exotherm control: avoid hot water; activate rolls sequentially; don’t keep wet gloves pressed on skin.

- Cool-air drying: after layup, use cool air; avoid direct heat sources.

- Soft edges: use moleskin to reduce edge pressure and contact dermatitis.

Build quality & imaging

Well-engineered resin systems deliver high strength with controlled final density, supporting excellent radiolucency for follow-up without cast removal.

Clinic quick checklist

- Stable lukewarm water + 2–5 s dunk + gentle squeeze.

- 30–50% overlap; width switching (7.5 → 10 cm) for long constructs.

- Post-cast CSM check and clear home-care warnings.

Conclusion & CTA

Mastering water-activated resin chemistry and the timing sequence (Dunk→Work→Gel→Set) separates flawless casts from problematic ones. Explore Optima Cast and Vian Cast specifications and sizes on our product page.