Resin Waste, Safety & Environmental Practices

Fiberglass casting tapes (synthetic cast bandages) use water-activated resins. After clinical use, leftover rolls, wet gloves, contaminated padding, and rinse water constitute “resin waste.” Without proper management they can cause skin irritation, odor, surface contamination, and extra disposal costs. This guide covers PPE, segregation, full curing, temporary storage, collection/transfer, and low-waste practices.

What counts as resin waste—practical groups

- Resin solids: fiberglass cast fragments, activated/unused roll ends, gelled/set layers, contaminated padding.

- Semi-solid/wet: wet gloves and gauze—let them fully cure/dry before disposal.

- Activation water: ideally kept clean; avoid contact with resin fragments to allow standard sanitary discharge under local clinic policy.

PPE & exposure control

- Gloves: thin nitrile; replace when soaked. Avoid prolonged contact of wet gloves with patient/skin.

- Eye/skin: eye protection when cutting/prepping; rinse any uncured resin off skin with cool water.

- Ventilation: dry bench with gentle airflow to reduce odor and trapped moisture.

The golden rule: make it inert by “full cure”

Risk is highest when waste is uncured or semi-gelled. Letting it fully cure in cool air turns it into a stable solid that is safer to handle and transfer.

- Extra roll ends: press onto a scrap cast or non-stick surface to cure into a “resin puck.”

- Wet gloves/gauze: leave to dry/cure fully, then place into the cured-solids container.

- Odor control: promote cool-air drying; avoid direct heat.

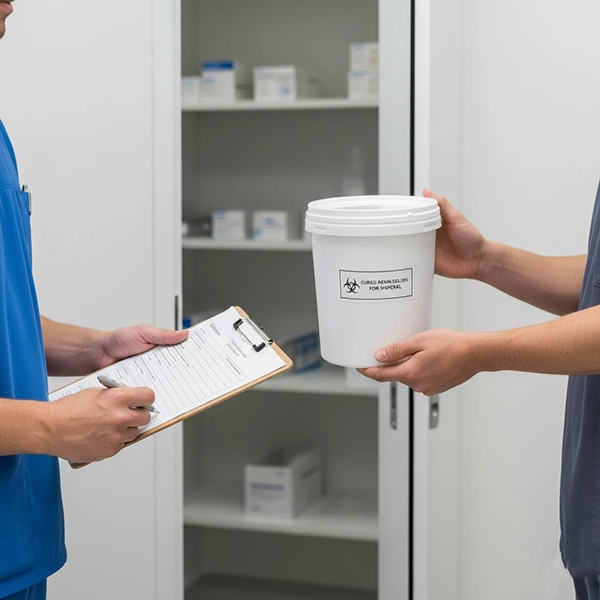

Segregation & labeling

- Cured resin solids: lined, lidded container with label—“Resin-Cured Solids,” date, and unit.

- Contaminated tools: separate from waste; clean blades/saws at a dedicated station.

- Liquids: prevent contamination of activation water by keeping fragments away.

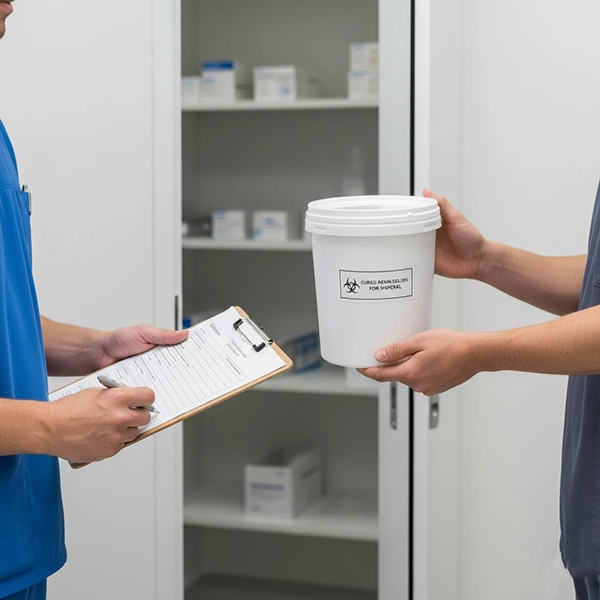

Temporary storage & transfer

- Limit moisture: keep lids closed; store away from heat sources.

- Schedule: clear containers periodically (e.g., weekly) to avoid buildup and odor.

- Internal traceability: simple form: waste type, approximate weight, date, responsible staff.

Low-waste, greener practice

- Realistic roll planning: Short Arm often needs one 3.6–4.6 m roll; for longer builds switch width (7.5→10 cm) rather than adding a full roll.

- Pre-staging: prepare padding/tools/position before wetting to avoid premature cuts.

- Team training: embed “short dunk—continuous layup—full cure” in the cast-room checklist.

FAQ

- Does fully cured solid still smell or irritate? After complete cure, odor and skin risk are markedly reduced.

- Bag semi-gel waste? No—cure first to prevent stickiness and odor.

- What about activation water? Keep it clean; if uncontaminated, discharge per clinic policy.

Clinic checklist

- Nitrile gloves, eye protection, gentle airflow.

- Separate containers: “Cured Resin Solids” / “Tools Cleaning.”

- Ensure full cure before disposal.

- Record dates and periodic transfers; refresh staff training.

Conclusion & CTA

With proper segregation, full curing, and standardized storage/transfer, clinics can protect skin and surroundings while managing costs. For a tailored checklist and staff training, please contact our team.