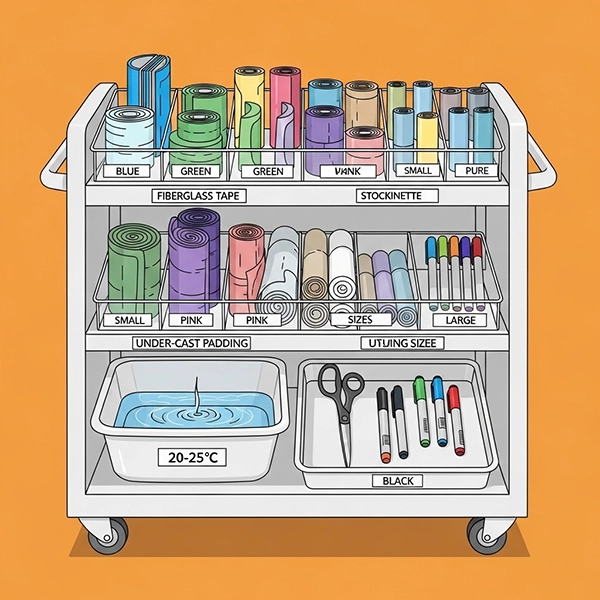

Successful casting depends on clinical skill and a complete, ready-to-use checklist of supplies. Your kit should cover both POP (plaster of Paris) and modern synthetics like fiberglass casting tape. Below is a practical, clinic-tested equipment checklist with storage tips and a step-by-step workflow to keep casting safer, cleaner, and faster.

With a complete checklist and good technique, casting becomes safer, faster, and more consistent. For high-quality fiberglass casting tape and professional casting supplies, visit our Behsou Shafa product page.