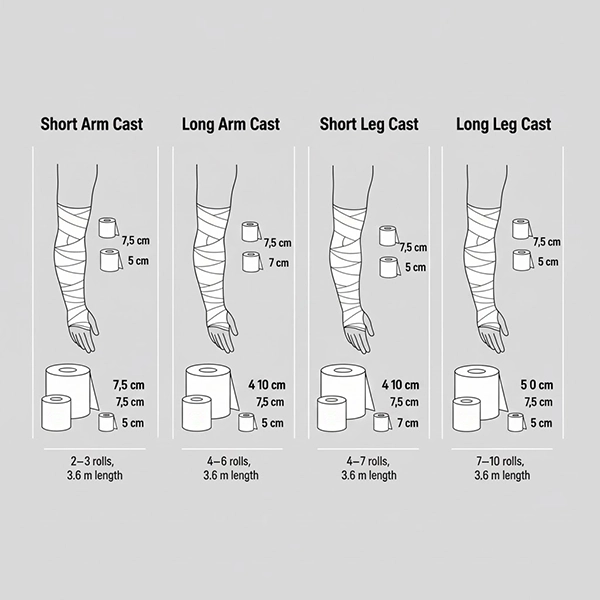

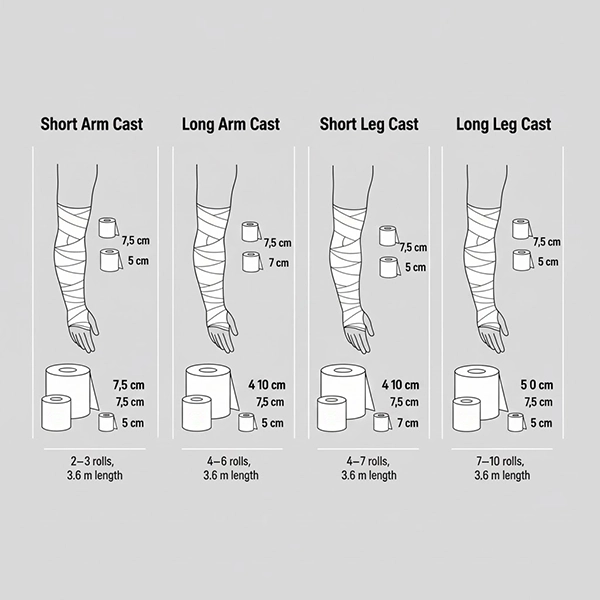

Fiberglass Casting Tape Size Chart: Choosing Width & Roll Length

Choosing the right width and roll length for fiberglass casting tapes directly affects molding accuracy, patient comfort, and structural stability. This practical size chart maps common widths (5, 7.5, 10, 12.5 cm) and standard lengths (typically 3.6–4.6 m) across adult/pediatric use, upper/lower limb casts, and hot/humid settings—with a stepwise selection logic.

General selection principles

- Coverage rule: width must allow smooth wrap with 30–50% overlap and minimal wrinkling.

- Edge control: the more curvature/bony prominences, the narrower the tape for maneuverability (e.g., 5 or 7.5 cm).

- Working window: in hot climates or with less-experienced teams, prefer shorter rolls to manage set time.

- Use efficiently: match roll length to cast length to minimize leftover waste.

Suggested widths by region & age

| Region/Age |

Suggested width (cm) |

Notes |

| Thumb/Wrist (Pedi) |

5 |

Excellent edge control, easier around curves |

| Wrist/Forearm (Teen/Small adult) |

5–7.5 |

7.5 cm is a common sweet spot for short arm casts |

| Elbow to hand (Long Arm) |

7.5–10 |

10 cm helps in long constructs and fewer wraps |

| Ankle/Lower leg (Short Leg) |

7.5–10 |

7.5 cm around malleoli, 10 cm up the calf |

| Thigh/Long Leg |

10–12.5 |

Stable progress over long distances, fewer layers |

| Veterinary (small limbs) |

5–7.5 |

High maneuverability around small curved areas |

How to derive width from limb circumference

- Measure circumference: at the widest part of the target segment.

- Divide by ~3 to 3.5: the quotient approximates the ideal width.

- Round to available SKUs: pick the nearest among 5/7.5/10/12.5 cm.

- Dry wrap test: simulate one dry turn to confirm no folds or overstretching.

Picking roll length & number of rolls

Common roll lengths are 3.6–4.6 m. For long casts, using two moderate rolls instead of one very long roll improves molding control and reduces premature setting risk.

- Short Arm: typically 1 roll (3.6–4.6 m), depending on width/body size.

- Long Arm: 1–2 rolls; plan 2 if extra reinforcement is desired.

- Short Leg: 1–2 rolls; large builds often require 2.

- Long Leg: 2–3 rolls; combine 10 and 12.5 cm widths for efficiency.

- Splints: often 1 roll; 2 for long/two-layer splints.

Hot/humid climates & learning teams

- Shorter rolls: better control of set time and fewer errors.

- Lukewarm activation water: avoid hot water to preserve the working window.

- Pre-setup: stage tools/padding/limb position before activation.

Quick picks (scenario-based)

- Pedi thumb/wrist: 5 cm width, 1 roll 3.6–4.6 m.

- Adult short arm: 7.5 cm, 1 roll (1 + extra half roll for large builds).

- Long arm: 7.5–10 cm, 1–2 rolls.

- Short leg: 7.5 around ankle + 10 up the calf, 1–2 rolls.

- Long leg: 10–12.5 cm, 2–3 rolls.

Execution tips for quality with less material

- Even 30–50% overlap with gentle tension; avoid excessive pull.

- Edge finishing with moleskin instead of excessive layering.

- For long constructs, switch widths mid-way (e.g., 7.5 → 10 cm) to optimize progress.

Conclusion & CTA

With a simple circumference check, consistent overlap rules, and smart width/length pairing, you can achieve precise molding, efficient usage, and stable immobilization. Explore available widths/lengths in Optima Cast and Vian Cast on our product page.