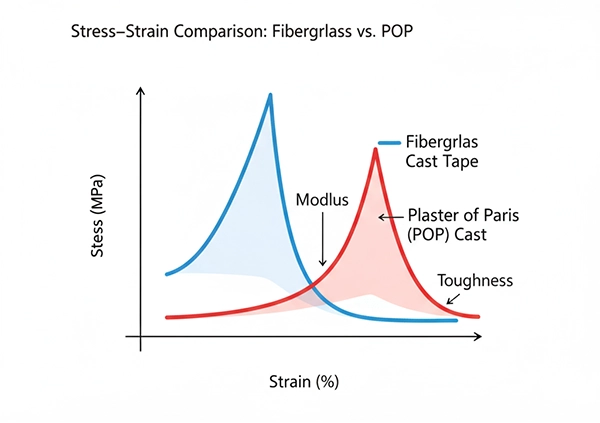

Understanding the mechanical properties of fiberglass casting tape is pivotal for stable immobilization and patient safety. The glass-fiber/rein resin system delivers high tensile and flexural performance at low weight with useful radiolucency. This overview covers tensile/elastic modulus, flexural rigidity, creep and fatigue, layup geometry (overlap/layers), environment (humidity/temperature), and cure quality.

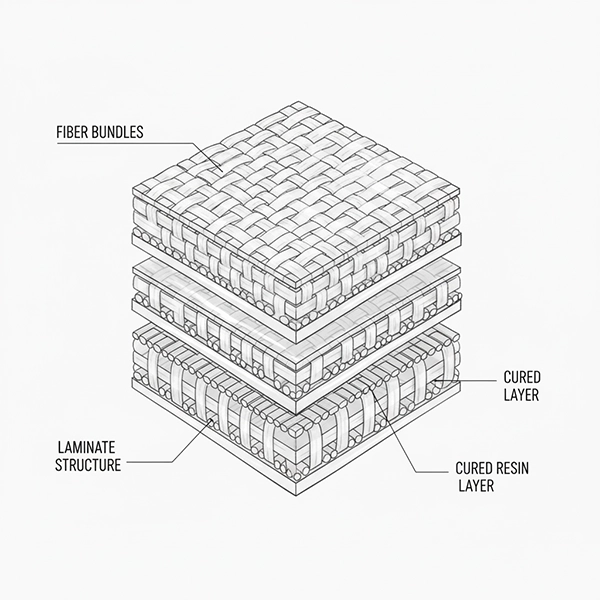

Glass fibers carry the load while the water-activated resin transfers stress and bonds layers. Higher effective fiber content and better alignment improve tensile strength and Young’s modulus. Ambient temperature and cure progression affect early modulus.

Clinical loads are predominantly bending. With ~50% overlap, each wrap yields ~2 effective layers; adding 3–4 layers at high-stress zones (e.g., malleoli, epicondyles) notably raises flexural stiffness. Uniform wrapping tension and palm molding prevent crease-induced weak points.

Over prolonged load, resin creep may add slight compliance, but glass reinforcement preserves dimensional stability. Under low-amplitude daily cycles, fiberglass generally outperforms POP—especially with uniform layup and complete cure.

Interlaminar shear depends on activation moisture, hand pressure, and gel time. Steady pace, constant overlap, and continuous mold & smooth reduce porosity and enhance layer bonding. Add 1–2 layers to edges and hot spots.

Optimizing fiberglass mechanical performance hinges on width/overlap choices, controlled activation, and proper cure. For high-quality fiberglass orthopedic cast bandages and technical specs, visit our product page.