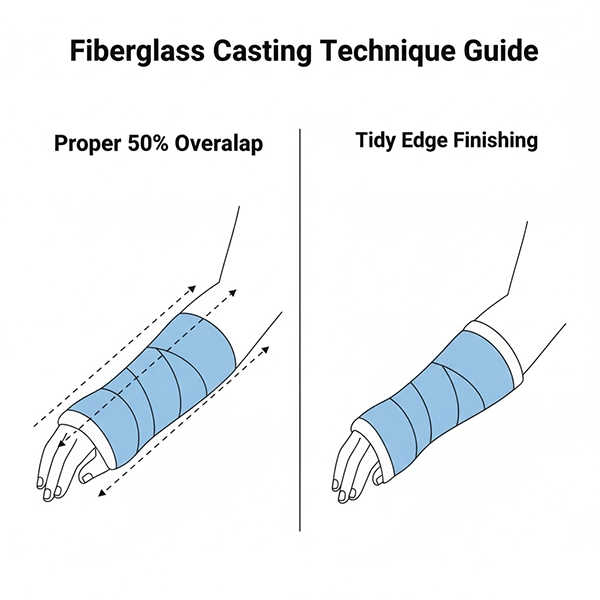

When applied and maintained correctly, fiberglass casting tape delivers strong, lightweight, and breathable immobilization. Yet a set of common mistakes during activation, layup, and daily care can compromise outcomes. This guide highlights key errors, warning signs, and practical fixes to prevent failures.

Prevent errors by choosing the right width, keeping overlap consistent, molding continuously, keeping the cast dry, and attending follow-ups. For case-specific guidance, contact our team.