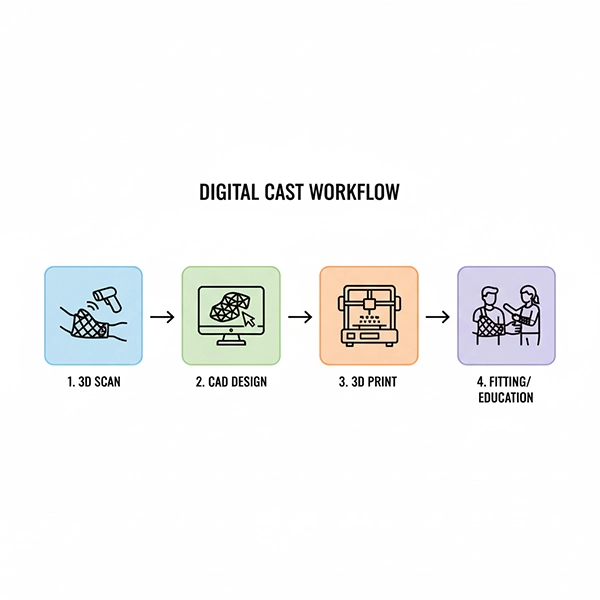

3D scanning and 3D printing are reshaping orthopedic immobilization. Instead of traditional POP or even some fiberglass casting tape use-cases, clinicians can capture limb geometry, design a ventilated lattice cast, and 3D print a patient-specific device. The result: improved fit, airflow, and a more modern care experience. This article outlines the workflow, benefits, limitations, and how to choose between traditional and printed solutions.

3D technologies open new horizons for custom casts, yet fiberglass casts remain advantageous in many routine and urgent scenarios. For case-by-case evaluation and choosing the right path (traditional vs. printed), contact us.